Pulp and paper industry water treatment

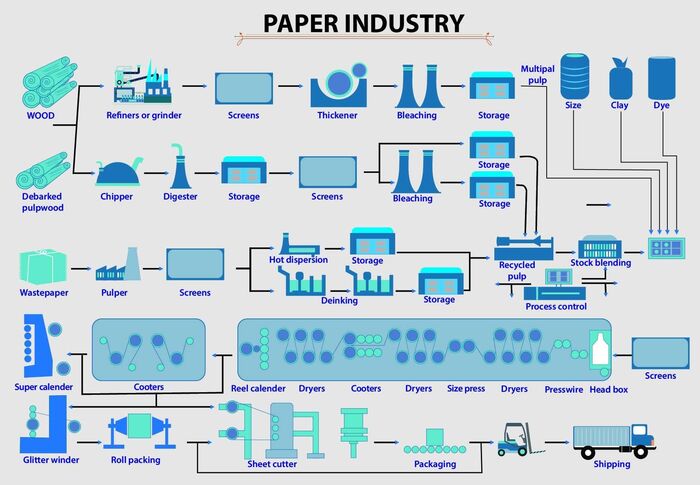

| This two kinds of industries are normally separated. The pulp (raw material for paper industry) and the paper industry, produce different kind of waste water. There is also a third related industry, the paper recycling industry, which has a similar kind of waste water. In the following text the three branches of industry are separated.

Production process, pulp industry The composition of pollutants in waste water of paper industries, depend on the kind of raw material which is used. For paper production wood, bagasse (outer stalk sugar cane), hemp, straw, etc. are used. Five basic procedures are used to produce pulp in an industrial way. The conduction of case can be with or without a bleaching process. If a bleaching process is also step of production, the Lignin will be destroyed. The effect is a whiter paper. The color depends also on the different kinds of wood or other raw materials which are used for the production. This step have the disadvantage to load the environment more, because of the use of chemicals like chlorine or chlorine dioxide (which are restricted, because of the process). |

|

|

|

|

The production of demineralised water for bleaching pulp and supplying boilers and cooling circuits:

- By coupling ultrafiltration with reverse osmosis

- By counter-current regeneration (UFD process), for good quality, softened water

- By ozone to bleach paper pulp and to ensure the absence of any remaining chlorinated compounds (AOX)

The treatment of waste water and sludge:

- By a physical/chemical finishing process, for the reduction of suspended matter and phosphorus

- By biological pre-treatment to eliminate carbonaceous pollution

- By biological process for diluted effluent and high water flow

- By a methanisation process, for granular sludge and to make use of the energy contained in the sludge

- By MBR, combining aerobic digestion with separation by ultrafiltration membranes

Furthermore, we offer a full range of services that cover complete operation of your water treatment installations, maintenance, technical assistance and leasing of mobile water treatment units to meet any temporary requirements (emergencies, maintenance, etc.).

- Guaranteed supply of process water, both in terms of quantity and quality

- Water savings

- Production of boiler supply water

- Ozone treatment to bleach paper pulp

- The treatment of waste water, effluent and sludge

- Cost reduction

We have a complete range of water treatment solutions for the production of demineralised water and the treatment of effluent from the paper industry.