[vc_row][vc_column][vc_column_text css_animation=””]

THE SOLUTION

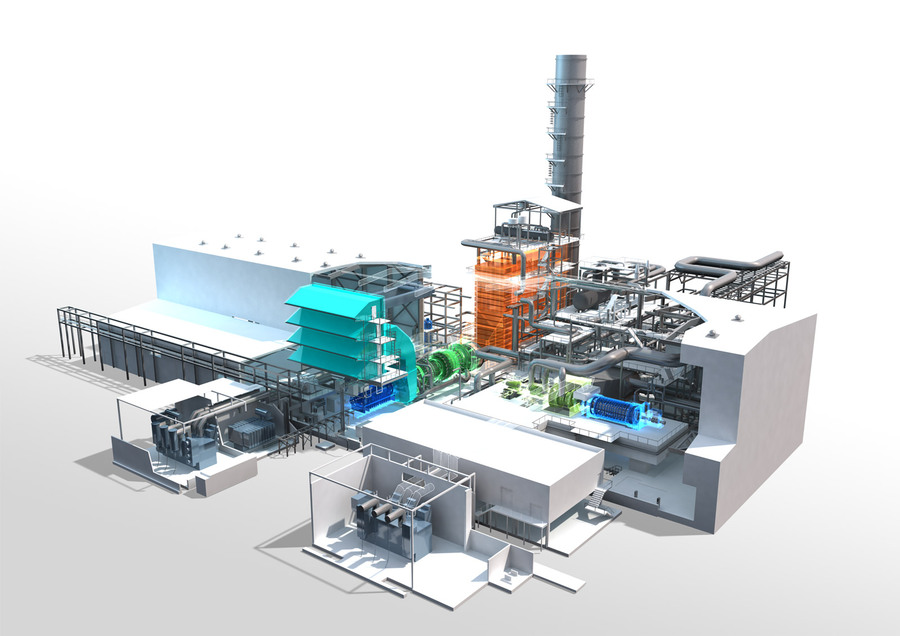

DTA have extensive expertise in delivering complete water and wastewater solutions for the Power plant is one of the important markets. The solution for each power plant consisted of 3 key elements which included a pre-treatment plant, a demineralization plant and a wastewater plant.

The pre-treatment plant is constructed to produce softened clarified water for the cooling tower water make up system critical for the plants operation. Two lime softening re-activators, each capable producing of treated water were utilized with associated chemical dosing systems. This included calcium hydroxide for softening, sodium hypo-chlorite for disinfection and oxidizing, polymer for flocculation, and sulphuric acid for the final pH correction. The sludge from the plant is then further treated by a thickener and dewatered through belt presses.

The demineralization plant then further treats water for the boiler make up water system. Clarified water from the pre-treatment plant is normally treated with sand filters to remove fine particulates, follow by reverse osmosis for Total Dissolved Solids (TDS) removal.

An ultra violet reactor is usually employed to break the Total Organic Carbon (TOC) before final polishing is performed in a mixed bed (to the required specification of water quality of less than 0.1 µ S/cm, Total Organic Carbon < 0.3 parts per million and Silica < 0.01 parts per million).

For the final stage of water treatment, DTA will delivered a wastewater plant consisting of two units of Dissolved Air Flotation (DAF) of highly refined wastewater (maximum of 150 parts per million of suspended solid in the effluent). The wastewater is then coagulated with a coagulant in two stage flocculators and followed by dissolved air flotation with final pH correction and chlorination before discharging. Sludge is then pumped back into the dewatering system.

DTA’s scope of work in delivering this solution included project management, overall plant and process design, equipment installation, guarantees, instrumentation, testing and commissioning

Fire protection

Power generation and distribution machinery, such as turbines, generators, transformers and cable tunnels, are capital-binding investments built to operate continuously without downtime. Utilizing the full potential of the power generation facility throughout its entire life-cycle requires the most effective and reliable fire protection available for each mission-critical production machine and space.

DTA provides high performance fire suppression that is safe for people, equipment and the environment. The DTA water mist system is both efficient and reliable, with proven protection against thermal stresses. Tested and type approved for a variety of spaces, DTA protects every critical area in each power generation and distribution facility, including:

- Gas turbines

- Diesel generators

- Steam turbines

- Hydraulic systems

- Transformers

- Cable tunnels

- Switch gears

- Electric cabinet rooms

- Warehouse and buildings

- Offices

Delivering unrivalled high performance and reliability, DTA is one of the best choice for turbine power plants, district heating stations, co-generation plants and power distribution facilities.

Customer preferences can be found more information regarding DTA water mist systems for power generation and distribution in both the systems section and the total flooding brochure. Please kindly send an email to info@datiar.com to receive all the details and catalogues.

Below is a list of systems typically found at electric generating stations:

- Fire pumps

- Hydrants

- Sprinkler/water spray systems

- Hose houses

- Halon systems

- Dry chemical systems

- Halon-alternative systems

- Carbon dioxide systems

- Detection/alarm systems

- Portable fire extinguishers

For Further Reading:

NFPA publishes several manuals and reference books covering specific systems, such as Fire Protection Systems; Inspection, Test & Maintenance Manual; Fire Alarm Signaling Systems and Automatic Sprinkler and Standpipe Systems. These publications can be obtained directly from the NFPA, telephone (800) 344-3555.

Other relevant codes and standards include the following, each of which can be ordered separately:

- NFPA 10, Portable Fire Extinguishers

- NFPA 12, Carbon Dioxide Extinguishing Systems

- NFPA 12A, Halon 1301 Fire Extinguishing Systems

- NFPA 17, Dry Chemical Extinguishing Systems

- NFPA 25, Testing, Inspection and Maintenance of Water-Based Fire Protection Systems

- NFPA 72, National Fire Code Alarm

- NFPA 1962, Care, Use and Service Testing of Fire Hose Including Couplings and Nozzles

[/vc_column_text][/vc_column][/vc_row]